In the realm of advanced holographic manufacturing, where precision meets innovation, Kiran Holographic stands at the forefront as a pioneering force in India. Established in 2002 in the vibrant city of Jaipur, Rajasthan, our company has evolved into a global leader, exporting cutting-edge holographic solutions to markets worldwide, including Dubai, Ahmedabad, and Mumbai. With a relentless commitment to quality, security, and technological excellence, we specialize in producing tamper-proof holograms, stickers, films, and machinery that safeguard brands against counterfeiting while enhancing visual appeal.

At the heart of our operations lies the High-Precision Step Transfer Machine – a state-of-the-art engineering marvel designed specifically for the holographic industry. This machine embodies our philosophy of “Powering Quality, “ ensuring that every hologram produced meets the highest standards of clarity, durability, and security. Whether for pharmaceuticals, electronics, luxury goods, or promotional applications, our Step Transfer Machine revolutionizes the production process, delivering unmatched efficiency and reliability.

What is the High-Precision Step Transfer Machine?

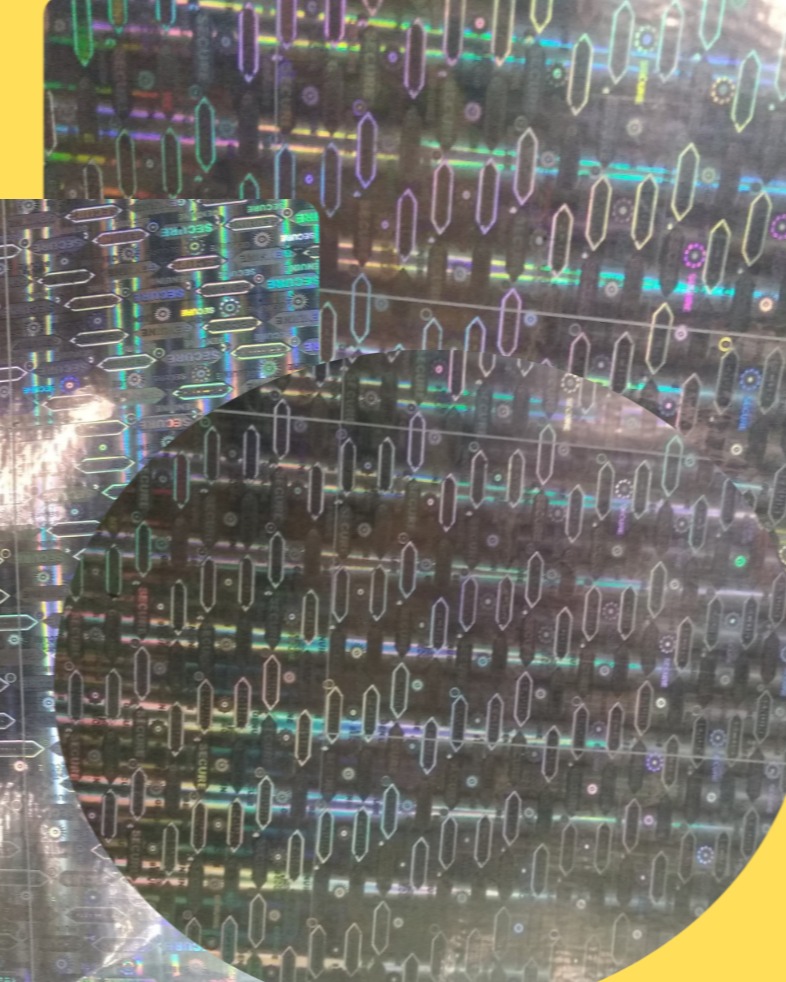

The High-Precision Step Transfer Machine is an automated recombining system, also known as a step-and-repeat embossing machine, optimized for mass-producing holographic images. It takes a single master hologram image from a nickel shim (the original metal plate derived from a holographic glass master) and precisely replicates it across large-format plastic sheets or films. This “step and repeat“ process involves incrementally positioning (stepping) the shim over the substrate and embossing (transferring) the image repeatedly under controlled heat and pressure, creating a seamless array of identical holograms.

Unlike traditional methods that rely on manual alignment or basic presses, our machine integrates advanced stepper motors for micron-level accuracy, ensuring zero distortion in 2D/3D, dot-matrix, or e-beam holographic patterns. Built with robust stainless steel construction and anti-vibration technology, it supports high-volume output while minimizing waste – ideal for scaling from prototypes to industrial runs.

Key Features and Benefits

• Unrivaled Precision: Achieves sub-micron registration accuracy using X-Y stepper controls, preventing misalignment that could compromise security features like microtext or kinetic effects.

• High-Speed Efficiency: Operates at speeds up to 500 repeats per minute, with adjustable parameters for various substrate thicknesses (e.g., PET films, polycarbonate sheets).

• Versatile Applications: Compatible with security holograms, promotional labels, hot-stamping foils, and transparent overlays. Supports customization for UV ink integration, serial numbering, and tamper-evident designs.

• Quality Assurance: Equipped with real-time monitoring sensors for temperature (up to 200°C), pressure (up to 30 tons), and N2 cleaning nozzles to maintain pristine surfaces, ensuring vibrant, forgery-proof results.

• Eco-Friendly Design: Energy-efficient heating systems and recyclable materials align with sustainable manufacturing practices.

• User-Friendly Interface: Computerized controls with touchscreen panels for easy setup, recipe saving, and remote diagnostics – perfect for operators at all skill levels.

This machine powers the quality that defines Kiran Holographic. By leveraging electroforming-derived shims and precise embossing, it guarantees holograms that not only dazzle with rainbow-like prismatic effects but also provide robust anti-counterfeiting measures, such as flip-flop images, hidden images, and laser-etchable serials.

How It Powers Quality in Holographic Production

At Kiran Holographic, quality isn't an afterthought – it's engineered into every step. The Step Transfer Machine integrates seamlessly into our full-spectrum manufacturing ecosystem:

1. Origination: We begin with holographic master creation using e-beam or dot-matrix techniques for intricate 3D/2D designs.

2. Electroforming: Nickel shims are produced via precise electro-deposition in our dedicated tanks.

3. Step Transfer (Embossing): The magic happens here – the machine transfers the shim's micro-relief structure onto plastic films under heat and pressure, replicating the hologram's light-diffracting properties.

4. Finishing: Post-embossing, metallization, coating, and die-cutting ensure polished, ready-to-apply products.

This closed-loop process results in holograms that withstand rigorous testing for authenticity, durability, and visual fidelity. Our machines have empowered global brands to combat fakes, with over 20 years of expertise backing every output. As a Made-in-India exporter, we offer cost-effective solutions without compromising on international standards.

Why Choose Kiran Holographic?

• Proven Track Record: Serving industries since 2002, with awards for innovation in security holography.

• Customization Expertise: Tail

Keywords

Sustainable holographic manufacturing practices

Precision hologram transfer technology

Anti-counterfeiting hologram manufacturing India

Mass production holographic embossing machine

Custom holographic solutions Jaipur Rajasthan

Durable security holograms and stickers

Automatic step-and-repeat embossing machine

Tamper-proof hologram production equipment

Advanced holographic manufacturing solutions

High-Precision Step Transfer Machine India