Kiran Holographics, based in Jaipur, India, is a leading manufacturer of holographic and security image technologies. Established in 2002, we specialize in **General Pattern Holograms** along with a broad range of security holograms, holographic films, labels, overlays, and hologram production machinery.

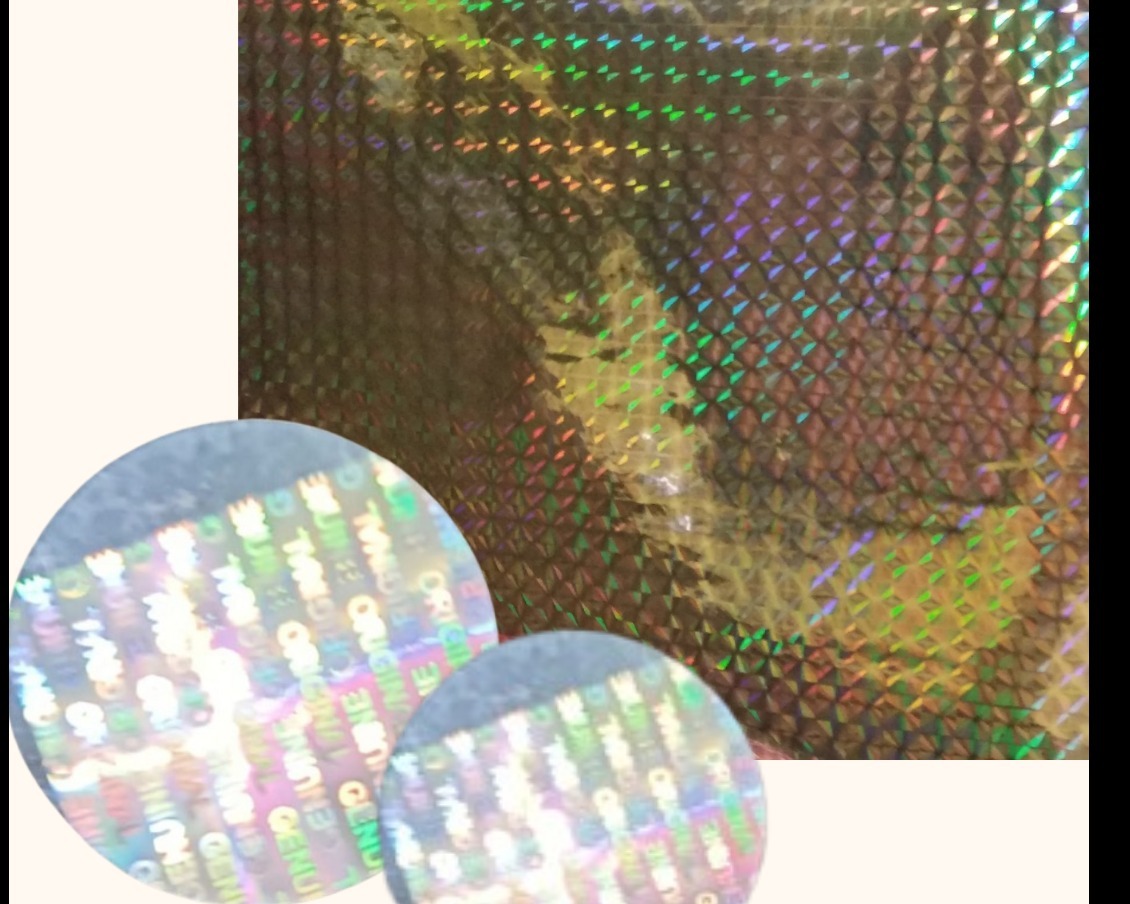

A general pattern hologram refers to a standard repetitive micro-optical diffractive design (such as grid, line, wave, moiré, crosshatch) that forms the base or backdrop of many holographic products. Such patterns are often combined with custom artwork, logo, microtext, latent image, or security features to create unique security labels or seals.

Production Workflow / Process

Below is a typical workflow for producing general pattern holograms (at Kiran Holographics or similar facilities):

Design & Artwork

Create or receive artwork, logo, text, security elements.

Integrate general pattern (grid, crosshatch, line, moiré) as a background diffractive pattern.

Add microtext, hidden images, latent images, variable data regions if needed.

Master Origination / Master Hologram Creation

Use laser optical set‑up to record the interference pattern between object beam and reference beam on a photo‑sensitive plate or resist.

This master becomes the glass master or photo master.

For general patterns, repeat patterns can be designed in the master.

Kiran offers “Holographic Master Origination” services, including 2D/3D, dot‑matrix, e‑beam, flip-flop masters.

Electroforming / Nickel Shims / Electro-Deposition

The glass master is used to electroform a nickel shim (negative) by depositing metal (nickel) — this creates a durable mold for embossing.

Kiran Holographic includes electro‑forming tanks in their in-house equipment.

Embossing / Replication

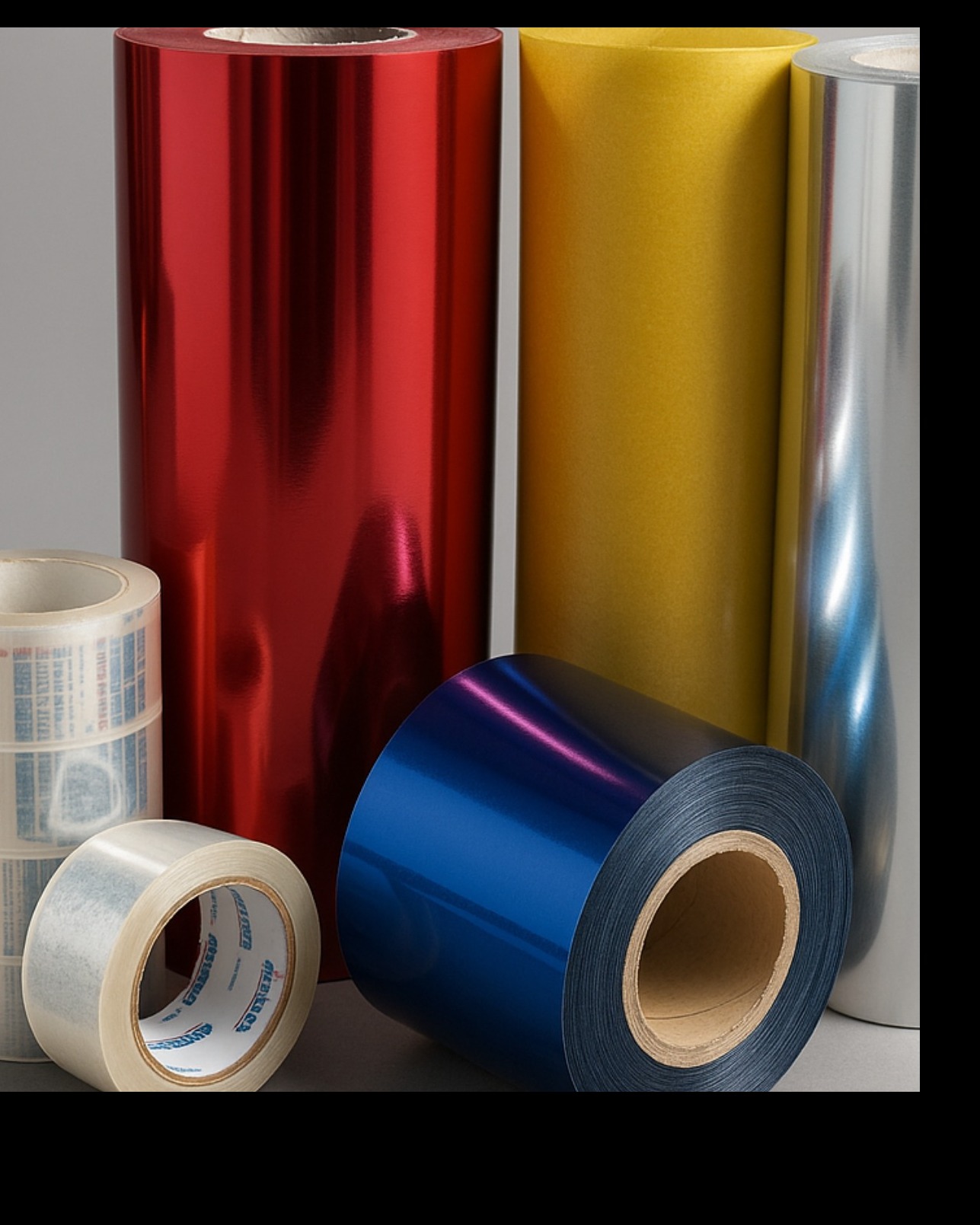

* The nickel shim is used to emboss (impress) the diffractive holographic pattern onto a substrate film (e.g. polyester PET, BOPP, aluminum foil) under pressure and heat.

* The embossed film carries the general pattern plus any overlaid security artwork.

Coating, Adhesive, Lamination

* The embossed film may receive a coating (protective lacquer) and adhesive applied, then laminated onto a release liner or secondary substrate.

* Kiran offers coating & lamination machines in their manufacturing line.

Printing / Variable Data

* On or after lamination, printing (e.g. ink or laser) can add variable data (serial numbers, barcodes, QR codes) atop the hologram.

* For roll / spool holograms, gaps between hologram segments allow printing of variable data.

Die Cutting / Slitting / Finishing

* The laminated holographic web is slit, die-cut, shaped (stickers, patches, labels) using rotary or flatbed cutters.

* Kiran provides high-speed die cutting, slitting, corner cutting machines.

Quality Control & Inspection

* Inspection under white light or laser setups to check registration, clarity, defects, uniformity.

* Final visual inspection ensures no flaws before dispatch.

Packaging & Dispatch

* Hologram labels or rolls are packaged suitably (sheets, rolls, reels) and shipped to clients.

Applications & Use Cases

* Security seals for documents, certificates, ID cards

* Brand protection labels / anti‑counterfeit tags

* Promotional / decorative holograms

* Holographic overlays (transparent) for cards, book covers

* Hot stamping foils (holographic)

* Holographic films for packaging

* Breakable / tamper-evident holograms

* Specialty labels: VOID, scratch-off, dual-color holograms

* Roll‑form holograms for high-speed application on production lines

Kiran Holographics lists product categories such as:

Hologram stickers, holographic strips, hologram void labels, hot stamping foils, holographic films, transparent overlays, breakable vinyl labels, etc. ([kiranholographics.co.in][5])

Key Features & Differentiators

* In-house full manufacturing chain: master origination, electroforming, embossing, lamination, cutting

* Capability for general pattern as base plus custom security features

* High precision machines: die-cutting, slitting, coating & lamination

* Variety of hologram types: 2D, 3D, dot-matrix, dual-color, flip-flop effects

* Customization for clients — logos, variable data, serial, QR, microtext

* Large production capacity and export readiness

General Pattern Holograms by Kiran Holographics

At Kiran Holographics, we specialize in creating General Pattern Holograms that serve as foundational diffractive designs for a wide range of security and decorative products. Using micro-optical repetitive patterns — such as grids, crosshatches, wave lines, moiré — these holograms are then overlaid with custom artwork, logos, latent images, or security features to produce distinctive and forgery-resistant labels.

Our state-of-the-art manufacturing facility in Jaipur is fully integrated: from master origination, electroforming, embossing, coating and lamination, to high-precision cutting and finishing. Our machines and processes ensure